Engineering

The Advantages of Our Engineering Services: Reduce Costs, Increase Speed and Output

Regardless of whether it involves reverse engineering, design of variants and customer applications or CAE services: We support our clients with routine engineering tasks.

Download the infographic relating to the ANTARES LCS Engineering Services here (free).

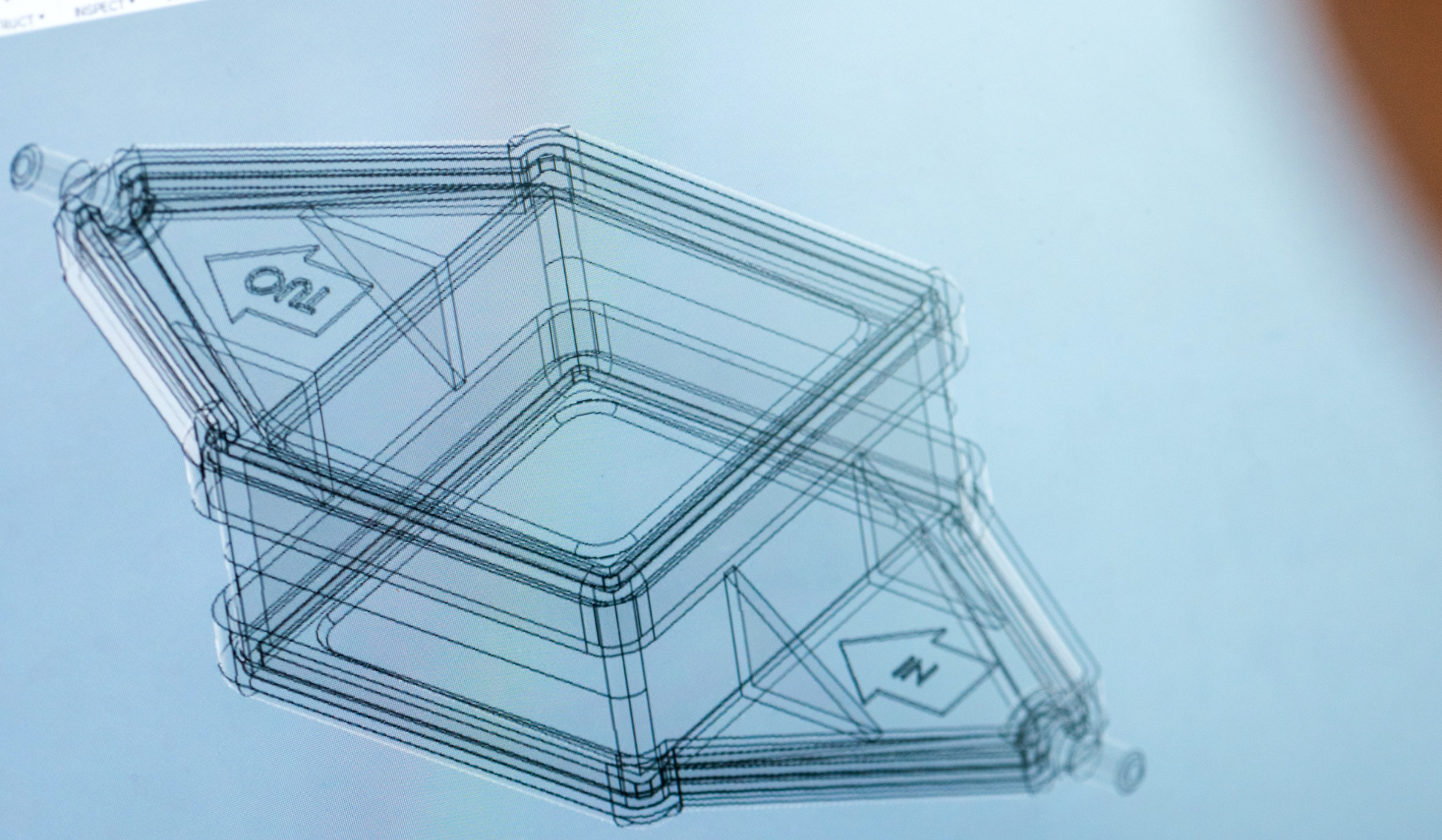

Reverse Engineering

Measurement of parts via optical and tactile procedures

Creation of 3D models

Creation of 2D drawings other documents

Complete documents are often missing for many older products (e.g. replacement parts). This can complicate reproduction using alternative processes that have been adapted to the updated lot sizes (e.g. 3D printing). In this case, the solution is to opt for a consistent reverse engineering approach from the initial component to the complete and up-to-date technical documents.

Variant Design

Creation of design variants and applications

You will be able to concentrate on your

core competences and get the capacity

and creative freedom to develop

your competitive advantage.

At the same time, you will gain

speed and flexibility.

Variant Optimization in Order to Reduce Complexity

Combining and adjusting variants

For example, by converting casting variants

into assembly variants

During the life cycle of product lines, more and more variants and customer applications are created – and due to high initial lot sizes usually as tool-specific designs. When the products then reach the end of their life cycle and are only being produced in small lot sizes, it makes sense to revise the design of those variants from tool-specific variants to assembly variants so that the least complexity is created for the supply chain

An Overview of Your Advantages

Up-to-date and complete product data for your replacement parts and variants

Fast and flexible support for your design team

Excellent quality

Maximum flexibility for your cost structure

Competitive prices using our location in India

German Engineering, Made in India

Thanks to our operating model you can utilize the advantages of offshore engineering for your project without the hazzles of time zones and language barriers! Your personal point of contact along with the project management is located in Weinheim, Germany, while we deploy our Engineering Center in Bangalore, India, for operational implementation. Our well-trained engineers have the most modern CAD systems at their disposal: Thanks to many years of professional experience (automotive, PowerTrain, filtration, and so on) they can implement your project very quickly and with the quality you expect, even in accordance with automotive industry standards. This saves costs and brings flexibility and resources “on-demand”.

In accordance with your specifications, we create the complete design documents for assembly units and components: 3D models, 2D drawings, bills of materials, and so on.

Want to learn more?

You want to learn more about the service offerings of ANTARES LCS GmbH? You want to discuss your project in detail? Or you have specific questions which we have not answered on our home page? Send us an email and we will get back to you as quickly as possible.