Slow-Movers and Spare Parts

Sourcing Solutions for a long Machine Life

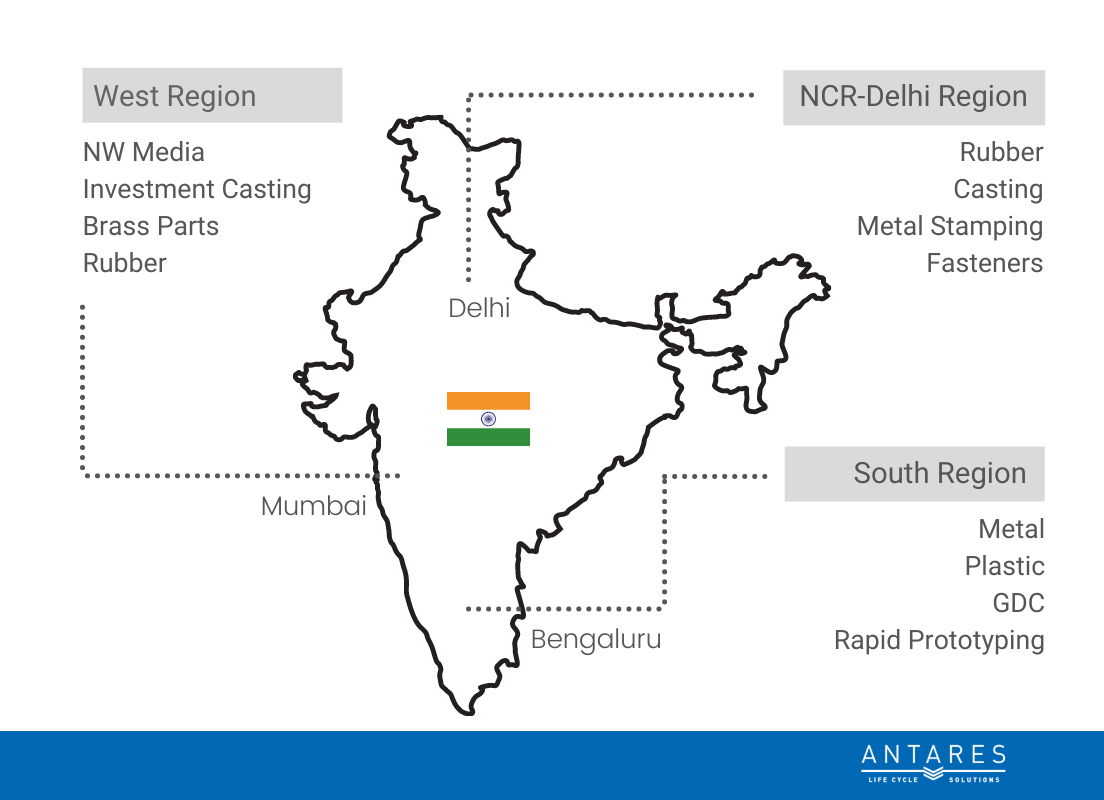

Components in small volumes, replacement parts which are difficult to source or have even become obsolete, requirements and customer demands that fluctuate substantially (and are therefore effectively unplannable):

All these are challenges in the day-to-day life of OEMs and TIER-X manufacturers in off-highway, commercial vehicles, mechanical engineering and many other industries when it comes to delivery performance towards end-customers.

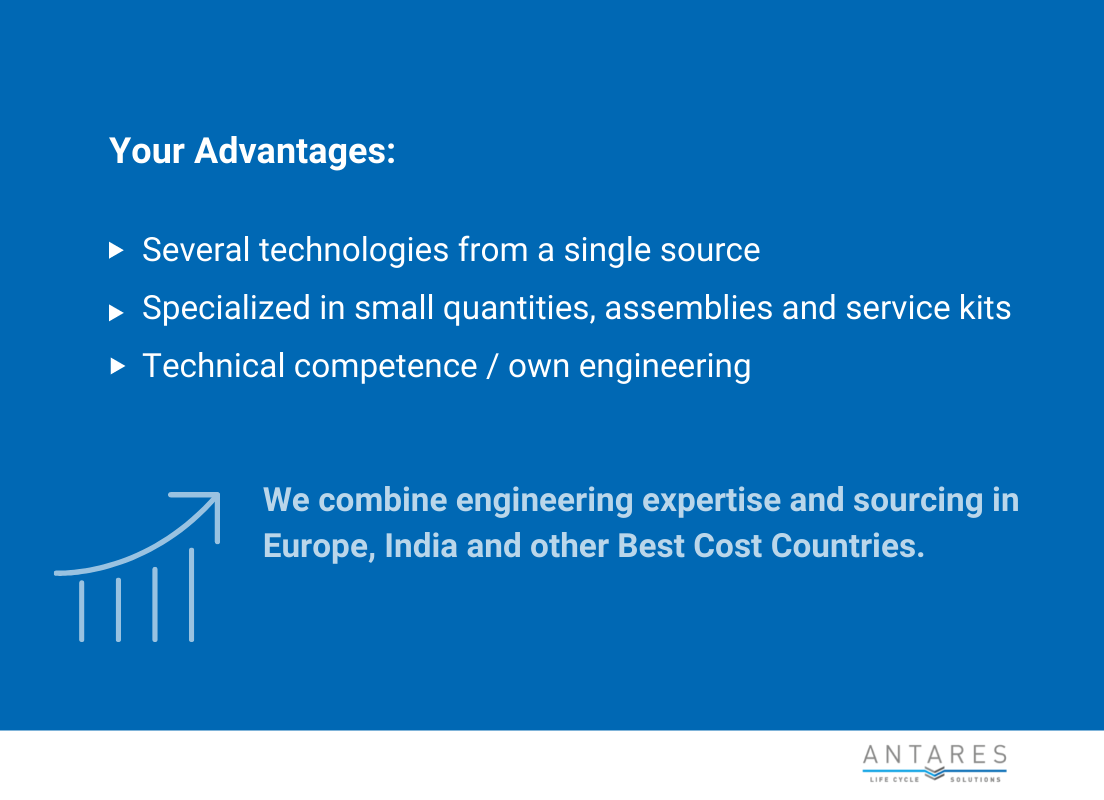

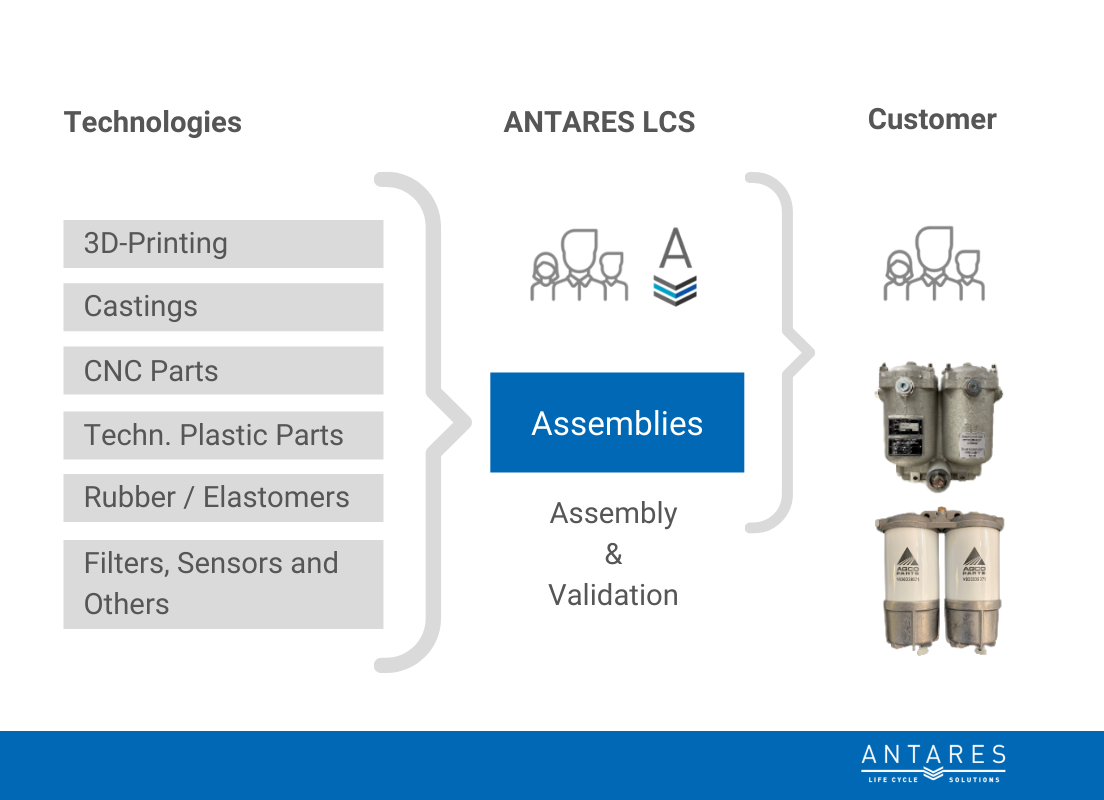

Our solution: for every case the most suitable manufacturing technology combined with our own experienced engineering team – everything from a single source.

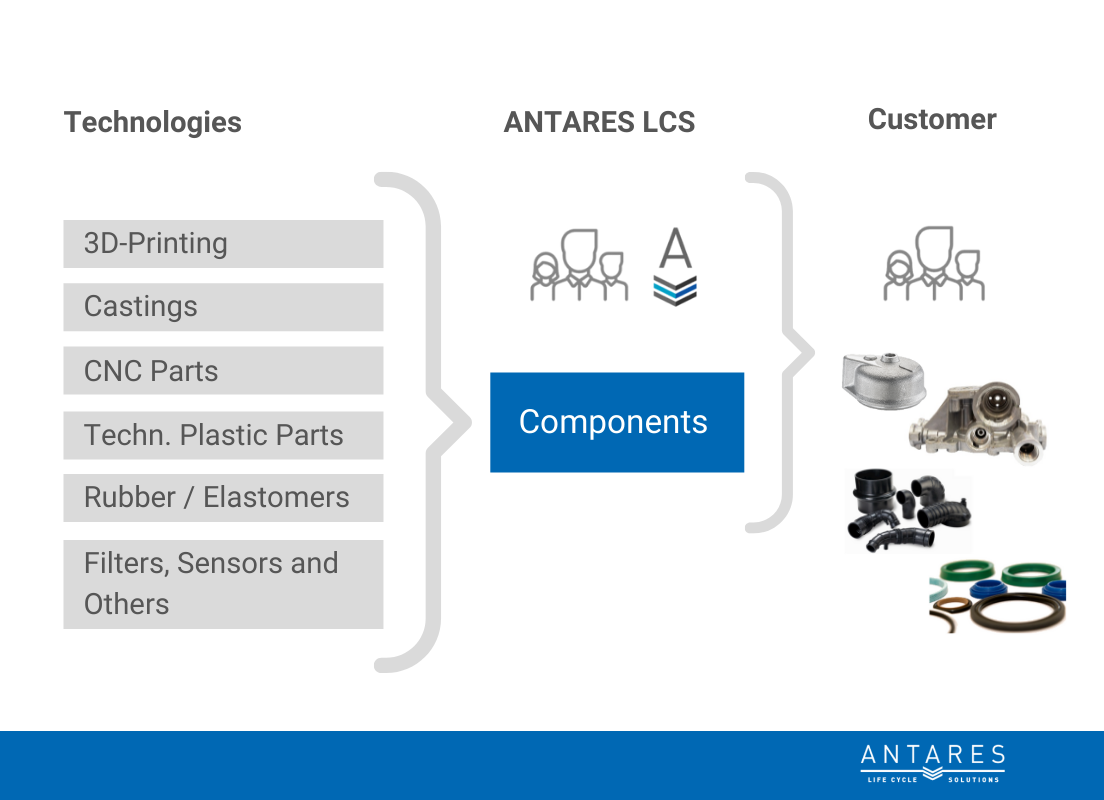

Technologies:

- Additive Manufacturing / 3D printing

- Casting Parts (sand casting, pressure casting and many more)

- CNC Parts

- Technical Plastics Parts

- Rubber and Elastomer Parts (gaskets)

- Assembly of Modules and Systems

- and many more

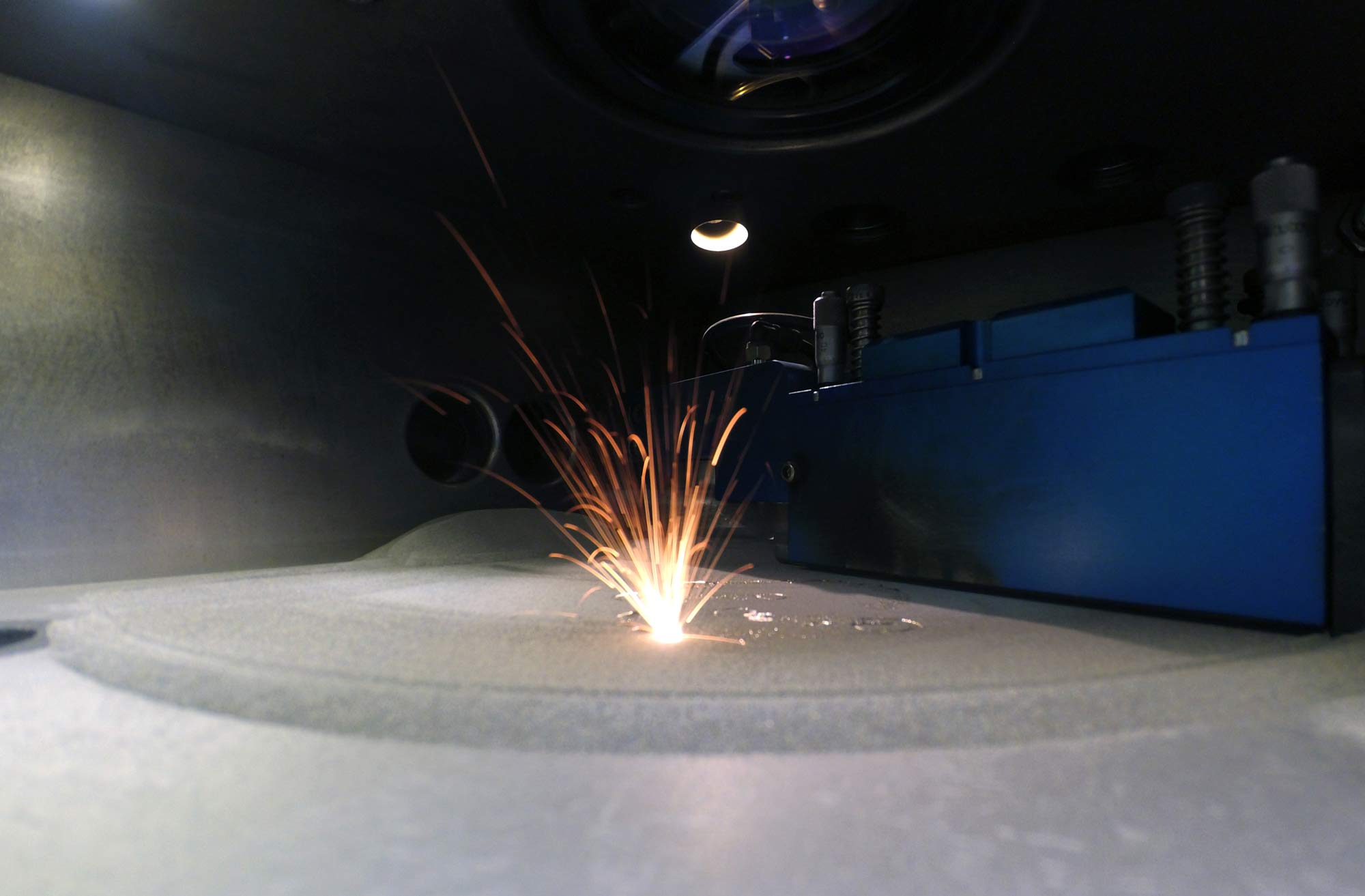

Benefits with Additive Manufacturing (3D Printing)

Shorter Delivery Times

Components manufactured with 3D printing are available much faster than cast parts created with conventional methods – this is because there is no need to create tools and plan setup times. This is a huge competitive advantage for small production batches.

Reduction of Inventory Stockpiles

With minimal batch sizes (from a minimum of lot size 1) and short replenishment lead times, 3D printing makes it possible to reduce inventory stockpiles for products to a minimum. Products with uncertain or fluctuating requirements benefit from this as inventory risks are minimized and cash flow is optimized.

Realization of Complex Component Geometries

Through 3D printing, it is possible to produce highly complex (e.g. bionic) structures that cannot be produced in any other way.

High Degree of Individualization

In addition to this, it’s possible to produce individual geometries and requirements more efficiently than with conventional processes.

Moreover, to round out our offerings, we also include the assembly of products and systems.

Want to learn more?

You want to learn more about the service offerings of ANTARES LCS GmbH? You want to discuss your project in detail? Or you have specific questions which we have not answered on our home page? Send us an email and we will get back to you as quickly as possible.