ANTARES Life Cycle Solutions

We are experts in life cycle management and will support you with engineering, supply of replacement parts and product range optimization. We use engineering and supply solutions to close gaps in your supply chain and optimize cost structures. Together, we will reduce your costs to free up space and give you more flexibility.

Our clients are OEMs and suppliers in investment goods industries like off highway and commercial vehicle manufacturing, mechanical engineering or plant engineering. ANTARES LCS specializes in the following services:

Engineering

Reduce Costs, Increase Speed and Output

Reverse engineering, design of variants and customer applications and CAE services: We will support your routine engineering tasks with our Engineering Center in Bangalore, India. This saves costs and brings flexibility and resources “on-demand”.

In accordance with your specifications, we will create complete design documents for systems, sub-assemblies and components: 3D models, 2D drawings, bills of materials, and so on.

Sourcing Solutions for Slow Movers

Improve your delivery performance and reduce complexity

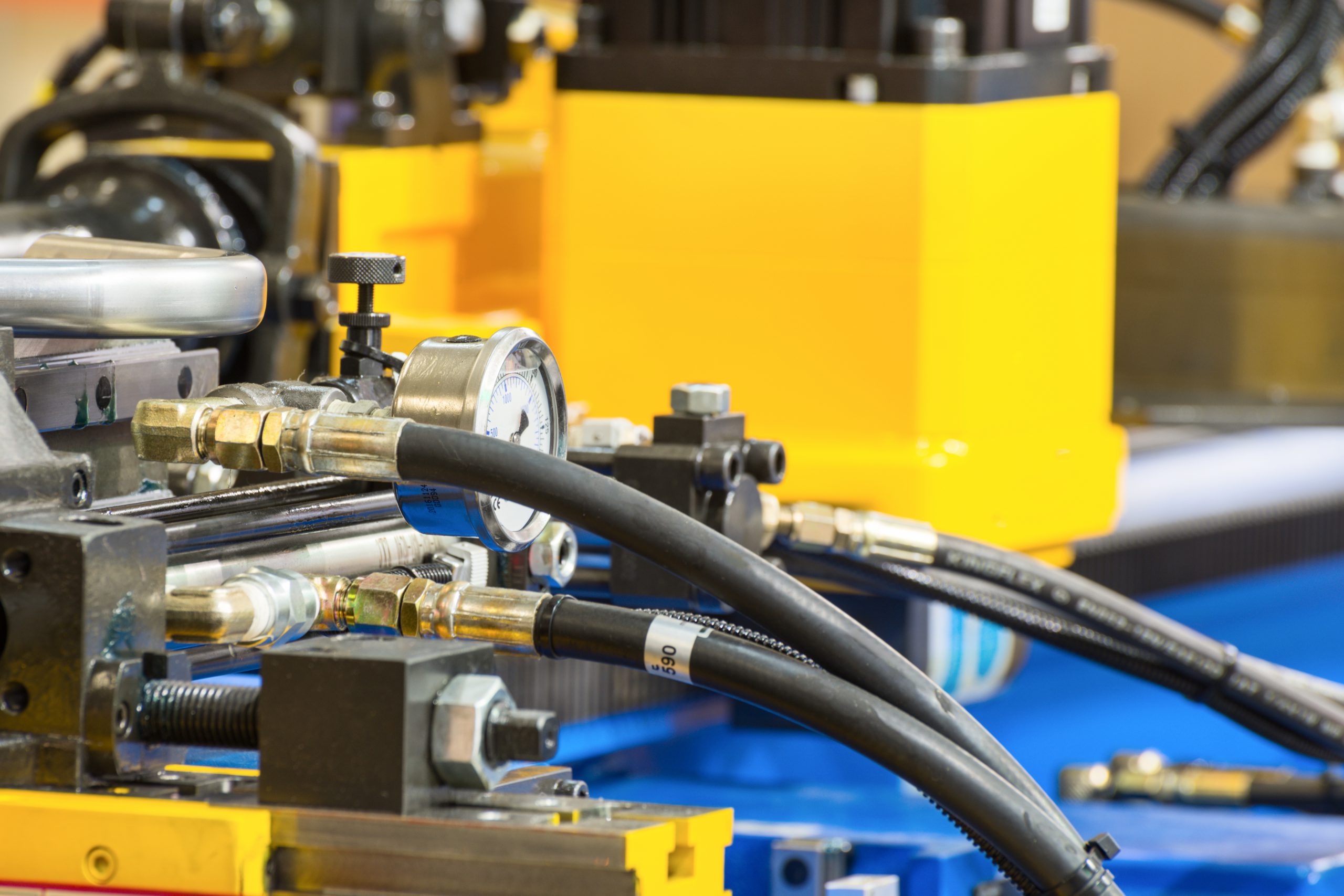

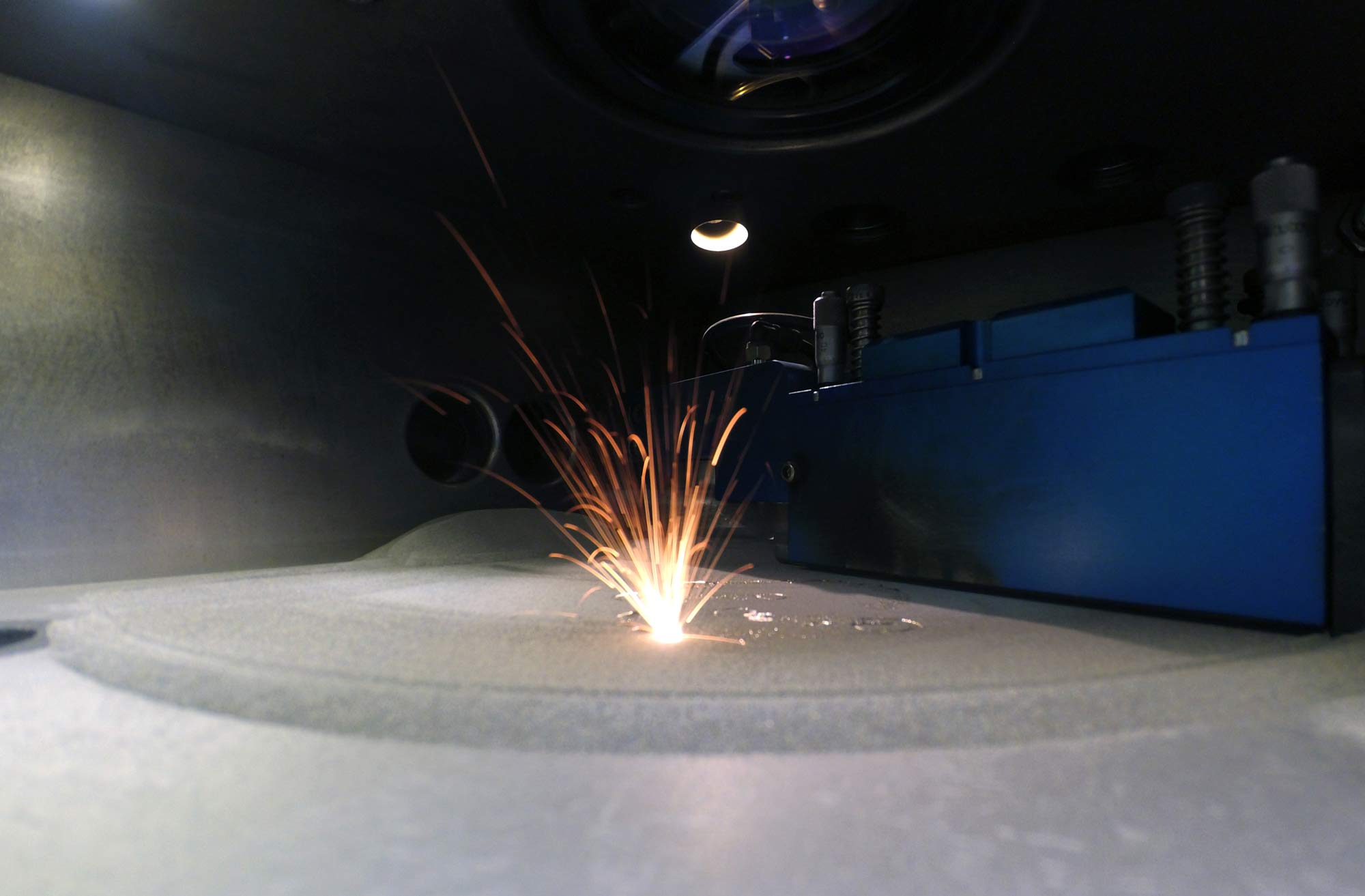

Our sourcing solutions for slow-movers and other spare parts include well-established manufacturing technologies like casting, CNC and others as well as 3D printing (also known as additive manufacturing (AM) along with assembly of modules and systems.

Conventional production technologies (e.g. casting) often lead to excessive inventory levels and create tooling costs. 3D printing of metal and plastic components can offer an efficient solution for many cases – the specialized area of the experts at ANTARES LCS.

Product Range Optimization

Streamline the Product Range, Optimize the Supply Chain

At many production companies, the product range offers substantial untapped potential to reduce costs and increase efficiency. This also applies to products at the end of their life cycle (keyword: obsolescence).

This is where the experts from ANTARES LCS will set to work and supply you with various solutions and support you during their implementation.

Additional Consulting Services

Diverse Expertise Coupled with Pragmatism

Our team has many years of experience working with diverse tasks and in diverse industries which we supplement with an excellent specialist network. Profit from our expertise:

- Technical consulting regarding filtration (off-highway, diesel motors, industry)

- Screening of product ranges regarding suitability for 3D printing

- Product management tasks (organization, tools, processes)

Industries and references

Our Industry Focus: Durable Capital Goods

We serve many diverse clients who work with the manufacture, operation and servicing of durable capital goods. In this regard, we work both for OEMs and for suppliers and service companies.

Examples of the industry segments that we serve:

- Off-highway and commercial vehicles

- Industrial engines

- Material handling

- Filtration, hydraulics, PowerTrain

- Engine repair and re-manufacturing

- Machine repair

- Mechanical engineering

- Plant engineering

We would be happy to provide you with references and project examples upon request.

Contact Options

You want to learn more about the service offerings of ANTARES LCS GmbH? You want to discuss your project in detail? Or you have specific questions which we have not answered on our home page? Send us an email and we will get back to you as quickly as possible.

ANTARES LCS

ANTARES Life Cycle Solutions GmbH

Cecil-Taylor-Ring 16-18

D – 68309 Mannheim

Germany

+49 621 950 404 80

info@antares-lcs.de