Typical problems of slow-mover products

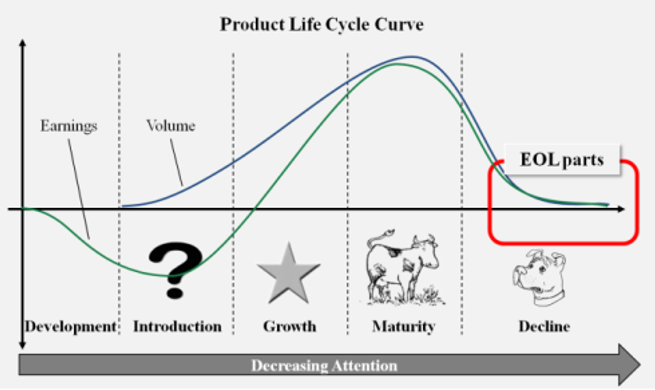

Initially companies are primarily concerned with innovations and thus with new technologies and products. In contrast, only a few (and then mostly larger) companies take a professional approach to the “long tail” of the Pareto curve (sales over product range), where processes and responsibilities are clearly defined and the product range is actually subject to comprehensive and regular maintenance.

However, it is precisely this “long tail” that conceals considerable potential for savings and efficiency gains. This potential is made up of:

– Storage costs and capital tied up by keeping parts that are not or only rarely needed in stock

– Keeping production facilities and operating resources in stock when capacity utilization is usually low

– Failure to adjust prices due to lack of awareness in the sales department

– Complexity in overhead functions such as Purchasing, R&D, QM, Product Management, Sales, Marketing

– Complexity in business systems (ERP, PLM) due to corresponding data volumes as well as maintenance efforts e.g. in Change Management

These costs are generally not transparent by the usual method of overhead costing, so that corresponding adjustments to the product range are either not carried out at all or are only carried out as part of special projects. Such projects are often triggered externally, e.g. by supplier changes, insolvencies of suppliers, material changes, changed ordering behavior of customers. Rarely do companies become active on their own initiative, and especially in sales there is a great deal of inertia regarding such products. Yet the targeted management of these parts would bring a whole range of valid benefits:

– Savings of directly attributable costs

– Increased sales through adjusted prices

– Reduction of complexity in production and logistics (processes, areas, parking spaces)

– Reduction of complexity in overhead functions

– Streamlining of business systems

ANTARES LCS GmbH helps its customers to generate sustainable savings of 0.5% – 2% of their turnover.

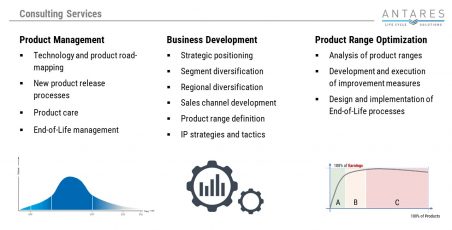

Our consulting services with the topic Product Range Optimization cover the following topics:

- Concrete recommendations for action based on comprehensive analyses (ABC, YXZ)

- Execution support during implementation and realization

- Introduction of sustainable systems and processes for assortment maintenance